To request a quote or inquire about custom release liners, please contact Rayven.

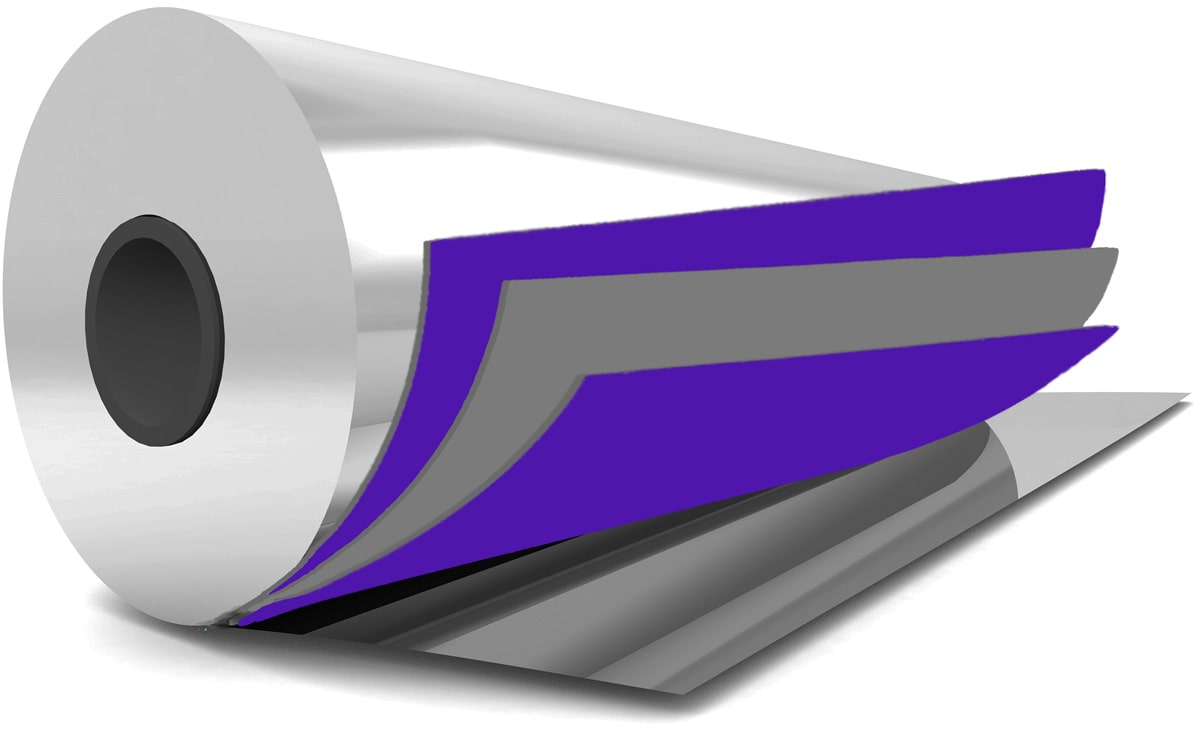

Release Liners

Release Liners

Rayven offers custom release liners with many different release chemistries and a range of release values, manufactured to match the adhesive system to the most precise silicone range. Rayven will match the chemistry to the application to yield the desired release performance. Substrate compatibility and heat resistance are also considered when choosing a silicone release coating.

Considerations include:

Release liners may also be referred to as release papers or release film.

Release Liner Values

Release Liner Values

The general categories of silicone release coatings that Rayven uses are thermal curing and UV curing. Within the categories, Rayven has several silicone resins and carriers. The carriers can be solvent, water, or 100% solids where no carrier is needed. Rayven is not limited to only one category of silicone; a broad selection of release solutions is available.

The release value of a system is measured as a peel value. Rayven can tailor a release system to meet a customer-specified range, or supply release liners that fall into Rayven’s standard release ranges. These ranges are as follows:

Standard Release Range*

- Premium 10-50 grams

- Easy 20-80 grams

- Medium 50-170 grams

- Tight 150-300 grams

- Extra Tight 200-400 grams

* Rayven test method 002a (RTM-002a) utilizes a 180-degree peel of an acrylic test tape at 300ipm.

A standard test tape will not correlate to a specific adhesive in many cases. In these cases, Rayven can build a testing program based on our customer’s actual adhesive (wet or dry) or unique test tape.

Release Liner Ranges

Release characteristics for release liners (release papers, release films, etc.) are almost always given as a range, not a specific number. Sometimes the range is generally specified as premium, easy, medium, or tight. This is true for most, if not all, release liner manufacturers.

The reasons for this are complex; below, Rayven reviews some of the main causes. The release force of a silicone coating is a relational value. It is not a specific attribute related only to the coating itself. Values like color and gloss are attributes that can be directly measured.

In most application situations, the customer would sample with a calibrated gloss meter, and displays the gloss reading. This same methodology is not accurate when working with a silicone release coating, which must be tested in relation to an adhesive of some type.

Because Rayven must test an entire adhesive and release liner system, a lot of variability creeps into the test results. This variability and lack of repeatability force the release liner manufacturer to quote release values in a broad range and not a specific value. The following factors affect the release value and correlation of a silicone and pressure-sensitive adhesive (PSA) release (or peel) value.

- The type of test tape used will affect the release test results. Different types of tape include acrylic adhesive, rubber-based, blended adhesives, film backings, fabric backings, etc.

- The variability of the test tape will affect the variability of the release test results. Most pressure-sensitive tapes have a large amount of lot-to-lot variation, many over 20%. The variability of the test tape will directly affect the variability of the release test results.

- Often, there is little correlation between the test tape and the adhesive used in the actual application. For example, the release liner manufacturer may use an acrylic pressure-sensitive adhesive test tape that is not similar to the hot melt pressure sensitive adhesive used in the actual application.

- The application temperature will affect the release value. Most liner testing is done in controlled laboratory conditions where the temperature and humidity are set. The adhesive may be applied at a much higher temperature or humidity in the actual application.

- Many commercial pressure sensitive adhesive (PSA) products rely on the hot application of the adhesive directly to the liner. Other PSA products involve a wet adhesive applied to the liner and then dried or cured in an oven (transfer coating). The release numbers for these products will have difficulty correlating to a room temperature test tape peel.

- Mechanical qualities will affect the release values of a liner. The smoothness or roughness of the liner substrate will affect the release value. A lot variation of the surface finish will usually give a corresponding variation in its release.

- The peel angle will affect the peel value of the test. Peel testing machines allow us to set the peel angle we use in our tests. If the application calls for peeling the product at a different angle, a difference in peel force can be expected.

- Different peel speeds will give different release values. Rayven uses a standard peel speed and peel angle in our quality control testing, but we can tailor these parameters to represent the actual intended application.

These are only some of the parameters that affect release testing results, but they demonstrate a lot more involvement than what looks like on the surface as a simple testing parameter.

Rayven can often customize the testing process to yield more relevant results for the specific adhesive and application parameters to give better testing accuracy with complex applications.

Release Testing for Release Liners

The standard test of a release liner or tape is called a peel test. This test involves peeling a test sample at a set speed and angle. The apparatus measures the force needed to peel the sample. The test output is the amount of force (grams are the typical units), average force, and peak force. Some release testing machines will show graphical output plots.

The testing of release liners utilizes a standard test tape. Rayven commonly uses Tessa 7475 tape (lot number controlled) as Rayven’s standard test tape. For accurate release testing with unique adhesives, Rayven can apply and test the customer’s actual adhesive or test tape.

Rayven Utilizes the Following Peel Testing Apparatus:

- Imass – SP2000

- TMI – TLMI Peel and Release Tester

Shear properties of adhesives can be evaluated with a shear testing tool. Rayven also uses a PSTC unit for this test.

Color and Gloss Testing

In many coatings, color and gloss are very important. This is especially true with inkjet coatings. Rayven test these characteristics with the following tools:

- BYK-Gardner, Micro-Tri-Gloss 20°60°85° gloss meter

- ColorTec-PCM – color, whiteness, and brightness testing

Coating Thickness Testing

Thick coatings such as adhesives and inkjet coatings are tested with TMI 49-70 digital measurement tools. Silicone release coatings are measured via X-Ray scanners from Spectro/ASOMA and Oxford Instruments. Rayven also has multiple Oxford Lab-X 3500 XRF analyzers for discrete sample testing. Coating thickness measurements are available for every roll produced by Rayven.

Other Testing Apparatus:

- Viscosity – Brookfield

- pH – Orion 420A

- Stiffness – Teledyne 150B, Taber V-5

- Friction – Kayeness

- Static charge – ETS

- Weight – various

Release Liner Values

Release Liner Values